关于工程纤维

About Engineering Fiber

早在几千年前,我国劳动人民已经使用稻草等天然植物纤维建造房屋,因此利用纤维作为增韧抗裂建筑材料并不陌生。《GB/T 21120-2007 水泥混凝土和砂浆用合成纤维》国家标准的出台,对于聚丙烯(PP)纤维、聚脂纤维、聚丙烯腈纤维和聚乙烯醇(PVA)纤维在水泥混凝土及砂浆中的使用进行了统一规范。

但是在建筑工程领域普遍使用的低强低弹模纤维如:聚丙烯(PP)纤维、聚脂纤维、聚丙烯腈纤维、纤维素纤维等与高强高模聚乙烯醇(PVA)纤维相比,抗拉强度、弹性模量低,断裂延伸率大,憎水性等特点 ,与混凝土自身弹模不相匹配,不能有效分担混凝土变形产生的拉应力,从而不能有效提高混凝土抗裂性能,因此,以聚丙烯(PP)纤维为代表的低强度低弹模纤维在混凝土中的使用受到严重局限。

As early as thousands of years ago, our ancestors started to build houses by using natural vegetable fibers such as straw, therefore, it proves natural to adopt the fiber for building material of strengthening toughness and resisting cracking. With the release of GB/T 21120-2007 Synthetic Fibers for Cement mortar and Concrete, use of PP, polyester, polyacrylonitrile and PVA fibers in cement concrete and mortar were further given unified regulations.

Low strength and low elastic modulus fibers commonly used in construction engineering: PP, polyester, polyacrylonitrile and cellulose, which are compared with high strength and high modulus PVA fiber, prove lower tensile strength and modulus of elasticity, while elongation at fracture higher with a nature of hydrophobicity, which will not match self-modulus of elasticity of concrete, failing to effectively share tensile stress and improving cracking resistance ability of the concrete. Therefore, low strength and low modulus elastic fibers such as PP fiber, are severely confined for concrete.

高强高模聚乙烯醇(PVA)纤维

High Strength and High Modulus PVA Fiber

聚乙烯醇纤维又称维纶,或PVA纤维。1924年由德国人发明将聚醋酸乙烯醇解制得聚乙烯醇,后以其水溶液用干法纺丝制得纤维。上世纪70-80年代,国外已经使用聚乙烯醇纤维代替石棉,生产波形纤维水泥板、瓦等建筑产品。二三十年后,日本KURARAY公司通过新工艺生产出可乐纶K- II纤维得到了很好的应用。

Polyvinyl alcohol fiber, also named PVA fiber, invented and made by Germans in 1924 through alcoholysis reaction of polyvinyl acetate, aqueous solution of which was later used in dry spinning to achieve fiber. In the 70 to 80s of last century, foreign countries had started to replace asbestos by polyvinyl alcohol fiber, to produce construction products such as corrugated fiber cement boards and tiles. 20 to 30 years later, KURARAY of Japan manufactured K-II fiber by new process, which was favorably put into application.

在我国,由皖维高新材料股份有限公司(1997年中国A股市场上市,股票代码600063)1992年开始研究维纶的工业化应用,成功开发了含硼碱性湿法纺丝工艺,并先后投资数亿元,形成年产3.5万吨的生产能力。皖维高新成立于上世纪七十年代,是目前国内出口高强高模PVA纤维的最大生产企业,占全国出口份额的80%,是世界上生产同类产品出口量仅次于日本的国内企业。目前国内生产高强高模PVA纤维的厂家很少,皖维高新公司生产的PVA纤维因为质量更好,规模更大,成为国内高强高模PVA纤维的制造龙头。上世纪末随着发达国家陆续取缔石棉,高强高模PVA纤维成为石棉替代品,作为增强增韧材料被广泛用于水泥基建筑板材中。

In China, Anhui Wanwei Updated High-tech Material Industry Company Limited (Listed in A share market in 1997, Stock code: 600063) started to study the industrial application of polyvinyl alcohol in 1992, successfully developed boron& alkaline wet spinning process and invested billions to form a production capacity of 35,000 tons. This company, incorporated in 70s of last century, became the biggest high strength and high modulus PVA fiber manufacturer and exporter in China, and accounts for 80% of the total, just second to Japan worldwide in terms of export quantum. There are few manufacturers of high strength and high modulus PVA fiber in China, and Anhui Wanwei Updated High-tech Material Industry Company Limited takes the lead in manufacturing of such product because of its product quality and scale. With constant banning of application of asbestos in developed countries in last century, high strength and high modulus PVA fiber has become its succedaneum and widely used in cement-based building boards as the reinforcing and toughening materials.

根据纤维混凝土的混杂理论,纤维分散越好,纤维在混凝土里面的分布越混杂、均匀,越能发挥纤维本身的能力,提高纤维混凝土复合材料抗裂作用。

高强高模PVA纤维作为水泥基增强材料在国外已有十多年广泛应用,但在国内大型工程中的应用却起步较晚,主要是因为未经改性的PVA纤维自生粘结较强,直接用于混凝土中不易分散,在混凝土内部成团分布,不能均匀分散的纤维混并不能有效提高混凝土的抗裂性能,相反容易破坏混凝土的整体性,在其内部形成更多的缺陷。

According to hybrid theory of fiber concrete, more the fiber decentralizes, more even and mixed it will be in concrete, and self-performance of such fiber will be well played to improve cracking resistance capacity of fiber concrete composite.

High strength and high modulus PVA Fiber has been widely applied for over ten years in foreign countries as reinforcing material for cement base. However, such product saw a relatively late use in many domestic large projects, mainly because of strong self-cementation of PVA fiber prior to modification, and it finds hard to disperse and form conglobation once directly used in concrete. Fiber will fail to improve the crack resistance performance of concrete without evenly dispersing, and in contrast, integrity of concrete will be damaged with more defects caused inside.

未改性PVA纤维(Unmodified PVA Fiber) 改性PVA纤维(Modified PVA Fiber)

改性聚乙烯醇纤维

Modified Polyvinyl Alcohol Fiber of Competence Technology

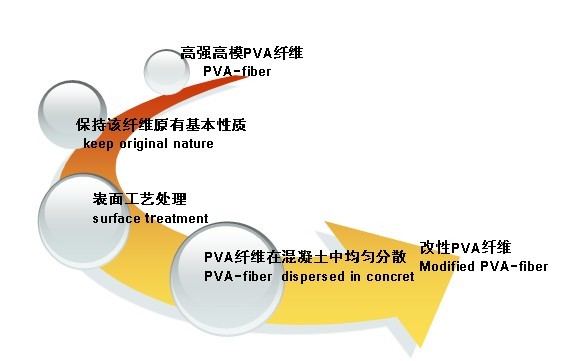

得益于PVA-ECC的前沿科技应用启发,能力科技联合国内高强高模PVA纤维龙头制造商皖维高新,在保持PVA纤维原有基本性能(高抗拉强度、高弹性模量)不变的情况下,通过与东华大学、河海大学等多家科研机构合作研究,对纤维表面进行特殊工艺处理,一举解决了该纤维在混凝土中的分散性难题,成功开发出改性PVA纤维(MPVAF),可以使PVA纤维在混凝土中均匀分散,乱向分布,直接运用于混凝土,使混凝土达到优异的性能,从而打开了PVA纤维在国内混凝土应用中的瓶颈,首次在水工混凝土中取得广泛应用。

Benefited from the application of frontier technology of PVA-ECC, Jiangsu Competence Technology Co., Ltd., with joint endeavor of Anhui Wanwei Updated High-tech Material Industry Company Limited—the domestic leading manufacturer of high strength and high modulus PVA fiber, and cooperation of Donghua University, Hohai University, Suzhou University and many other scientific research institutions, conducted special process treatment to fiber surface and successfully developed modified polyvinyl alcohol fiber (MPVAF), on the basis of keeping original basic performances (high tensile strength and high modulus of elasticity) of PVA fiber, to resolve the dispersing problem of such fiber in concrete and allow PVA fiber to evenly disperse and distribute disorderly. Application of this product can be directly used to concrete to help achieve outstanding performance, and therefore, overcome the bottleneck in application of PVA fiber concerning concrete in China and lead to a wide use in hydraulic concrete for the first time.

|